Ensuring first-class quality at KEMMLER Electronic is of central importance, especially when it comes to the requirements of the automotive industry. The IATF 16949 certificate acts as a decisive benchmark for compliance with the highest quality standards in all phases of production, from planning to delivery. Here, KEMMLER Electronic not only commits itself to top quality, but also demonstrates its willingness to fulfil the demanding standards of the automotive industry.

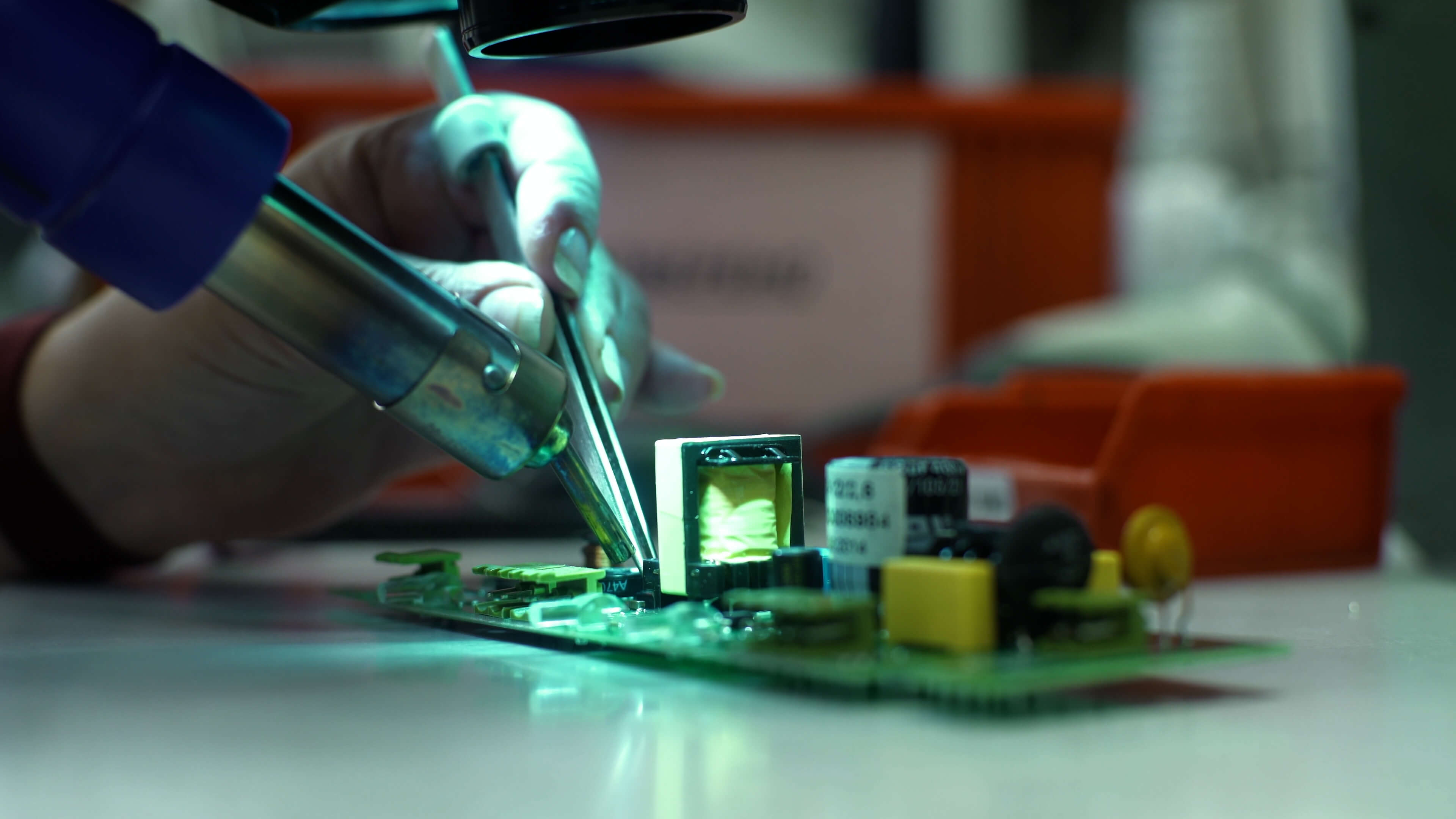

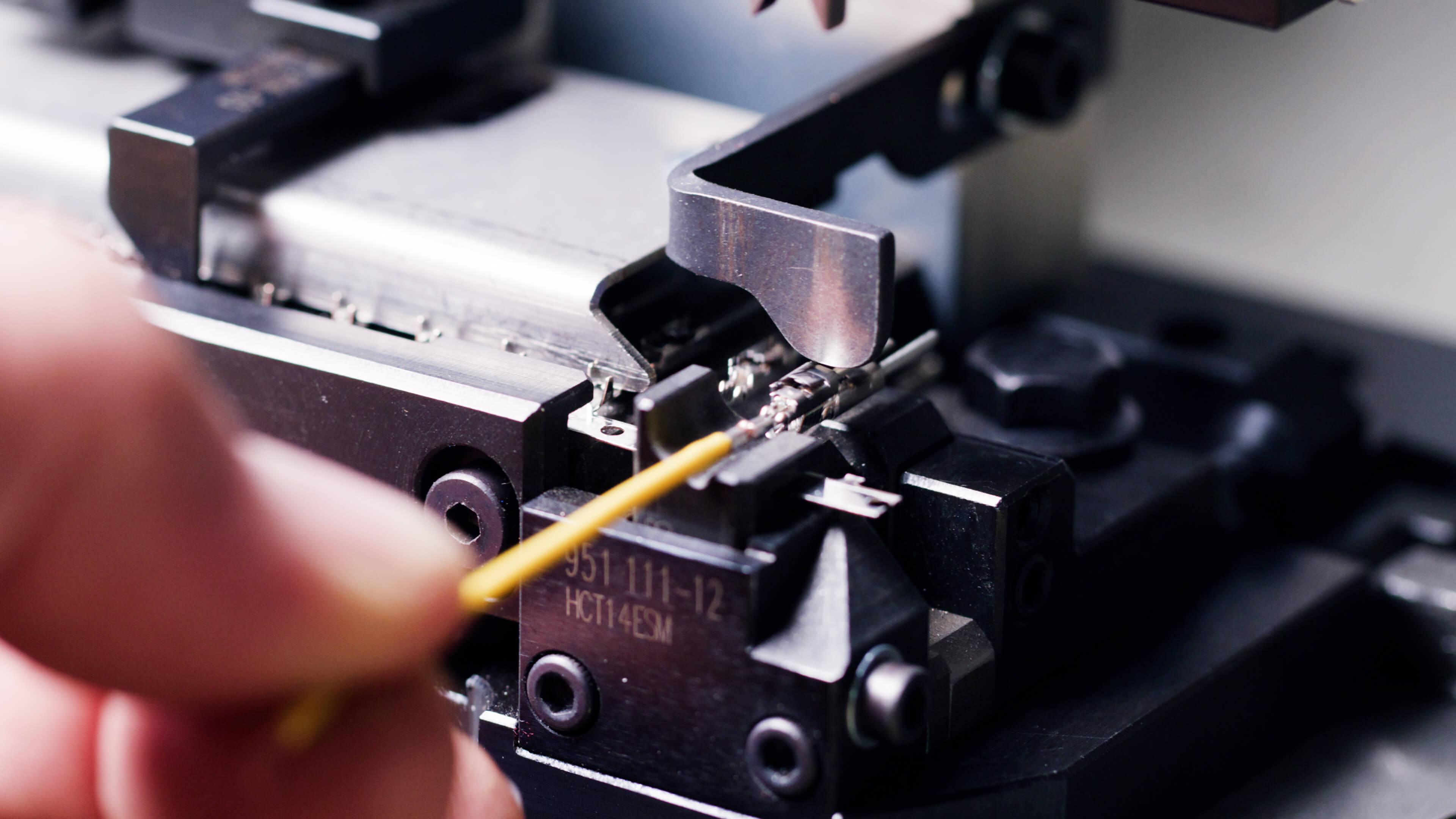

The certification emphasises the importance of an efficient quality management system that focuses not only on the end product, but also on the entire manufacturing process. This is particularly relevant at KEMMLER Electronic, as the components we produce are an integral part of vehicles. Errors in the connection technology can not only lead to malfunctions, but also to safety risks.

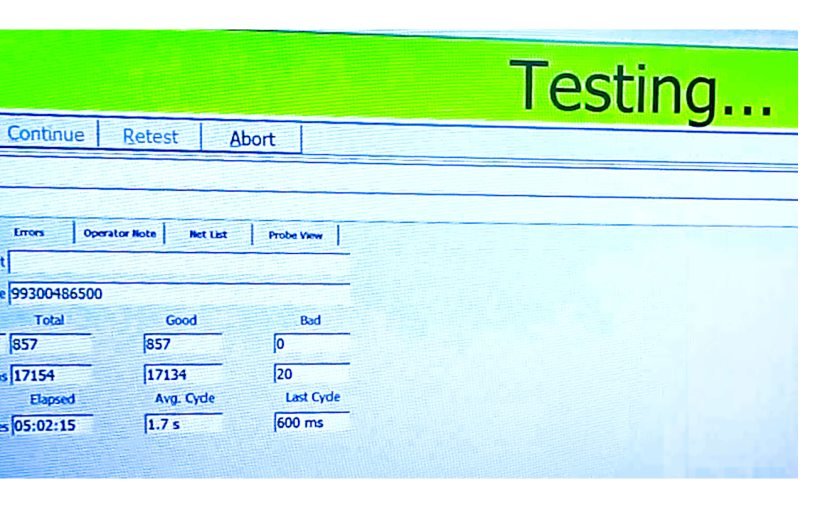

The IATF 16949 certificate strengthens customer confidence by setting clear guidelines for quality management and continuous improvement. Companies that achieve this certification undergo regular audits to ensure the highest standards. Overall, our certificates help to recognise and rectify potential problems at an early stage, which significantly improves quality.